Menu

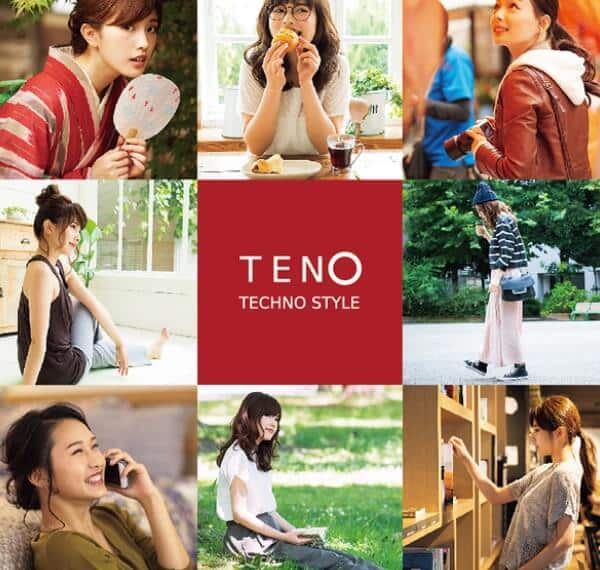

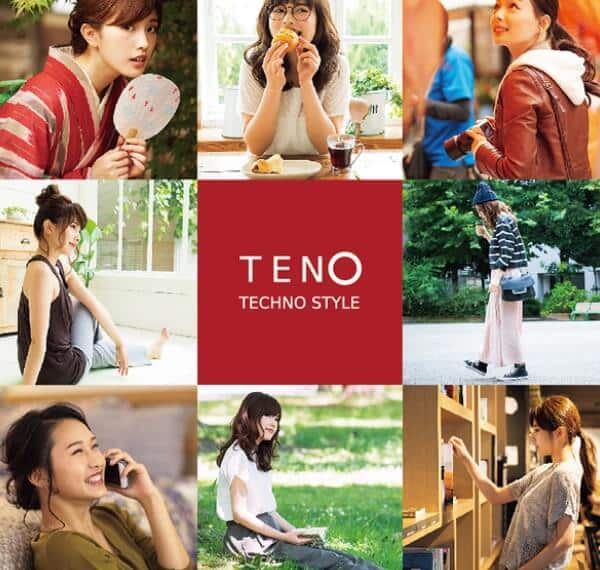

“LET ME SHOW & SHARE

MY STORY WITH YOU”

TENO was raised originally by UTAX In JAPAN. UTAX was established in 1956 in Japan, specializing in the manufacturing & supplies of components to the world of initimate fashion industry from Tokyo to New York, Milan, Frankfurt, London, Paris, Barcelona, Bangkok, Hong Kong, Singapore & many other European, North & South America, Oceania & Asian destinations. UTAX has developed & operated the very first non-seam intimate products since 1998 with a winning innovative apparel in Lyon-France Mode City in 2004.

Launched its first offshore large scale supply chain in Chiangmai-Thailand under the flagship of UTAX F.M. THAILAND in 2012 for Oem and with TENO brand began in 2014. Since then, with every expertise and knowhow that we pioneering the non-seam apparel.

We have engineered the technology into the science & art of making original seamless apparels not only for intimate fashion, but to the world of sports, life-styles, medical supports to meet the new next, today.

TENO products are all auto or some with semi-auto machine made, the closest Artificial Intelligence products that TENO could achieve and deliver commercially today. With this Smart Technology,

TENO is capable of and aim to design, architect, engineer a next generation of smart garment not only for technological intimate apparel, but also high-tech lifestyle & sportswear. With this technology, we promise that all TENO garments are being made at a high-tech friendly environment and responsive to every social responsibility. A product that could sustain the future for all of us, right from producers to consumers ,a sustainable future.

Brand Identity; Products of every TENO is made from the very exclusive quality of Free-cut or Clean-cut fabrics with or without other supplementary components.

TENO co-works and partnering with World-class knitters to select, develop and engineer the most exclusive

TENO-CLASS high-tech finest Free-cut/Clean-cut fabrics, guaranteed.

Today, most of our products (NSP) are made by automatic machine, virtually these garments that you’re witnessing are computer programmed, artificially-automatically or semi-automatically machine system made. A smart technology that allows a clean & fast flow of production turn-around time, quality assurance, production & material management, permitting us to

change the landscaping of the traditional supply chain cycle.

Al is actually being used more than you might think …..

We, UTAX JAPAN will initiate, pursue and move forward to fully integrate the Al technology into our TENO NSP production system. A few more good steps to go in realizing the Al (artificial interlligence) and change the traditional way of apparel making, logistic and the entire supply chain system in the Intimate Apparel business.